About the Center

EFRCs (Energy Frontier Research Centers)

The Center for Lignocellulose Structure and Formation (CLSF) is an Energy Frontier Research Center (EFRC) initially established in 2009 by the US Department of Energy to accelerate fundamental research and scientific breakthroughs in energy-relevant areas to meet critical energy challenges of the 21st century. EFRCs integrate the expertise of multiple leading scientific investigators to enable fundamental research of a scope and complexity that are beyond beyond the capabilities of single investigator or small-group research projects and to provide an environment that encourages high-risk, high-reward research that would not be done otherwise. The CLSF received a second round of renewal funding in 2018 based both on our achievements to date and the quality of our proposal for future research. More information about the Department of Energy's EFRC program can be found at the DOE EFRC website.

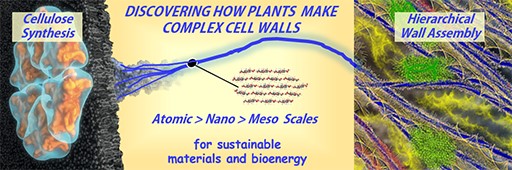

Our mission: CLSF is working to dramatically increase our fundamental knowledge of the physical structure of biopolymers in plant cell walls to enable fresh insights and perspectives into the formation and structure of these highly useful, energy-rich, renewable biomaterials.

Understanding the fundamentals of cell wall structure and assembly may open new frontiers in bioenergy and biomaterials technologies based on cell wall engineering. Plants are important sources of renewable energy and carbon-based materials for society’s needs. Our center focuses the complementary talents of biologists, physical scientists and engineers to uncover the well-kept secrets of how plants build microscopic threads of cellulose and assemble them with other polymers to make complex structures. These structures – ‘cell walls’ - have versatile properties unmatched by current industrial materials. The insights gained in our research could inspire new ways to tailor energy-rich biomaterials and to mimic biological methods to make new kinds of materials.

Partners

The EFRCs are called to be synergistic: our strength is the collaborations between researchers with different backgrounds: biologists, physicists, chemists, engineers, computational scientists. Penn State University is the lead institution with partners at North Carolina State University,University of Virginia School of Medicine, Massachusetts Institute of Technology, University of Rhode Island, University of Texas at El Paso, University of Cambridge, Louisiana State University and Oak Ridge National Laboratory each of which contributes special expertise to the Center. Please visit our People page to learn more about each of our Senior Investigators' research interests.

Lignocellulose Focus

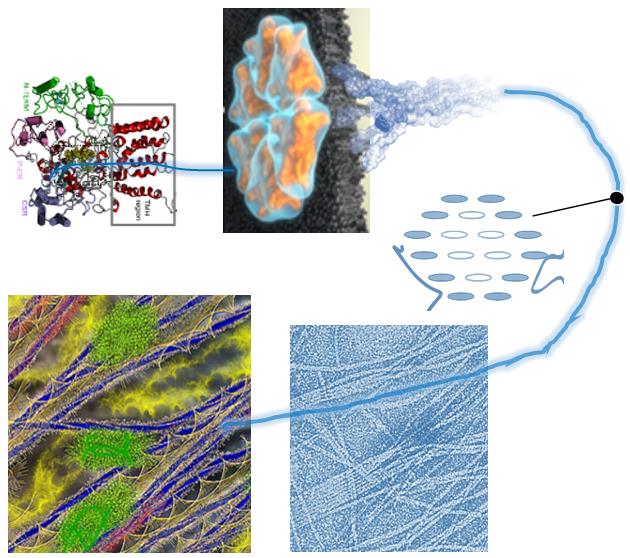

Lignocellulose is the major structural material of plant bodies and constitutes the enormously important biorenewable resource used to make building materials, paper, textiles and many polymer derivatives. At the nanoscale, lignocellulose is a highly versatile composite of three complex biopolymers, namely, crystalline nm-scale fibrils of cellulose which are linked together by less-ordered polysaccharides (such as xylans) and embedded in lignin, a complex and heterogeneous phenolic macromolecule.

Despite its huge economic importance, many questions about how plants can convert soluble sugar into high-strength crystalline cellulose microfibrils and combine them with other polymers to make cell walls with diverse physical properties. Plants lock up the majority of their stored photosynthetically-captured solar energy in their cell walls: lignocellulose is an important biomaterial and the largest store of renewable solar energy on Earth. Honed by 500 million years of evolution and refinement, the nanoscale construction of the plant cell wall endows it with a remarkable combination of mechanical properties and resistance to enzymatic and chemical attack. Its intricate and complex structure makes the wall recalcitrant to conversion to biofuels, necessitating expensive and energy-intensive pretreatments as an early step for biofuel production. A deeper understanding of the physico-chemical interactions underlying cell wall structure and its assembly may open new frontiers in bioenergy and biomaterials technologies based on cell wall engineering. This research can offer insights into ways to synthesize complex, hierarchical biomaterials and to modulate the chemical, mechanical and other physical properties of such biomaterials.

- Want to know more about how plants build their cell walls? Watch a public lecture by CLSF’s Director Daniel J. Cosgrove entitled “Sunshine Into Wood: How Plants Build Their Cell Walls, a Gigaton Source of Renewable Materials and Energy" presented as part of Penn State University's Sustainability Lecture series. The lecture starts with the big picture of plant cell walls as a source of renewable material and energy, provides a look at our current understanding of how the plant cell wall is constructed, and answers questions on how this energy and material is harnessed in society today, how science progress is aided by big research centers such as the Energy Frontier Research Centers including CLSF. (February 2021)

Our Work

CLSF continues to enhance its state-of-the-art transdisciplinary research to uncover the details of plant cell wall structure and cellulose microfibril formation. The work of our center is organized around these basic questions:

- What are the key structure/function relationships in plant cellulose synthases (CESAs)?

- What is the structure and composition of the plant cellulose synthase complex and how does it produce the cellulose microfibril?

- How are nano- and meso-scale structure and assembly linked to growth and mechanics in primary cell walls?

- What are the nano- and meso-scale details of secondary cell wall structure, and how are they formed during secondary wall synthesis?

How do plants synthesize para-crystalline cellulose microfibrils?

How do plants synthesize para-crystalline cellulose microfibrils?

The center is comprised of a unique mix of experts in computational modeling, biochemistry, biophysics, biopolymer analytics, cell biology, genetics, molecular biology, polymer physics, synthetic chemistry, and systems biology specifically chosen to work synergisterically to tackle key questions of lignocellulose structure and formation, using both experimental and theoretical (including computational) approaches.

Outcomes

The fundamental knowledge and technical expertise to be developed by the Center is essential for designing novel ways to manipulate plant cell walls, an important step in unlocking the energy-rich cell wall for the next generation of sustainable biofuels and for creating new cellulosic biomaterials with diverse economic applications. Additionally, the understanding of how nature creates this most versatile of biocomposites could be used to create new composites based on different polymers.

More information

- CLSF University of Virigina researchers tapped the power of cryo-electron microscopy to determine the structure of a cellulose synthase CesA homotrimer, published in Science 7/9/2020. This new discovery unveils the molecular machinery that plants use to weave cellulose chains into cable-like structures called “microfibrils.” “Cellulose proto- and microfibrils are only a few nanometers thick -- a nanometer is a billionth of a meter. But their strength is in their numbers…When assembled, the resulting structure is very strong. You might think of it like how pieces of dry straw can be packed to make a durable, waterproof thatched roof.” Read more about the relevance of these findings on how the plant makes cell walls.

- Read an approachable article written by one of our PhD candidates, Amin Makarem, that describes one of our avenues of research: Unraveling how nanoscale fiber movements lead to plant growth potentially benefits biofuels - Spotting Tiny Movements When a Plant's Cell Wall Expands

- View Research Poster highlighting avenues of research in the CLSF (2019)

- View our mission as a poster using simple terms and images: "Powering your car with sunlight"

- View Project Summary

- For center members only, please see our internal wiki page for more information.

About the website

Web design and development services were provided by Patricia Craig. Website updated by Amanda Snyder and Laura Ullrich (Gilliland).